Fuel Management

The optimal use of fuel assemblies can generate substantial savings for nuclear power plants. Do you want to know how you can apply this to your facility? Use our innovative software!

Nuclear Fuel Management Software

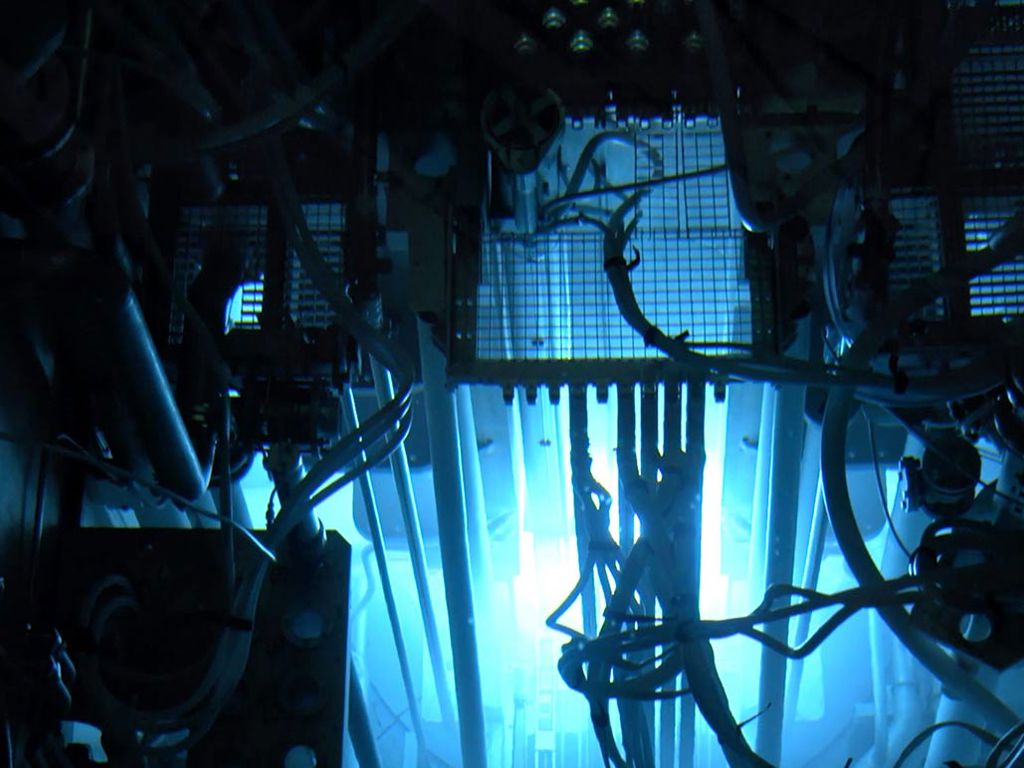

How can you reduce the operating cost of your assets without compromising on safety and availability of capacity? Nuclear power plant operators are under continuous pressure to achieve this task. To help you with this problem, we developed fuel management software: ROSA and SOSA. The main goal of our fuel management software is to reduce fuel cycle costs within a range of technical or regulatory constraints. ROSA allows you to optimise the loading pattern of your reactor core. SOSA minimalises the reload time of the reactor core.

ROSA - Optimise the loading pattern of your reactor core

ROSA is nuclear fuel management software, specially designed for pressurised water reactors. ROSA calculates the power distribution in the core in 3D together with over 70 optimisation parameters such as:

- Natural cycle length

- Thermal peaking factors

- Shutdown margin

The more complex the problem, the better ROSA performs. ROSA is very user friendly and has an intuitive user interface. A tool designed by reactor engineers, for reactor engineers.

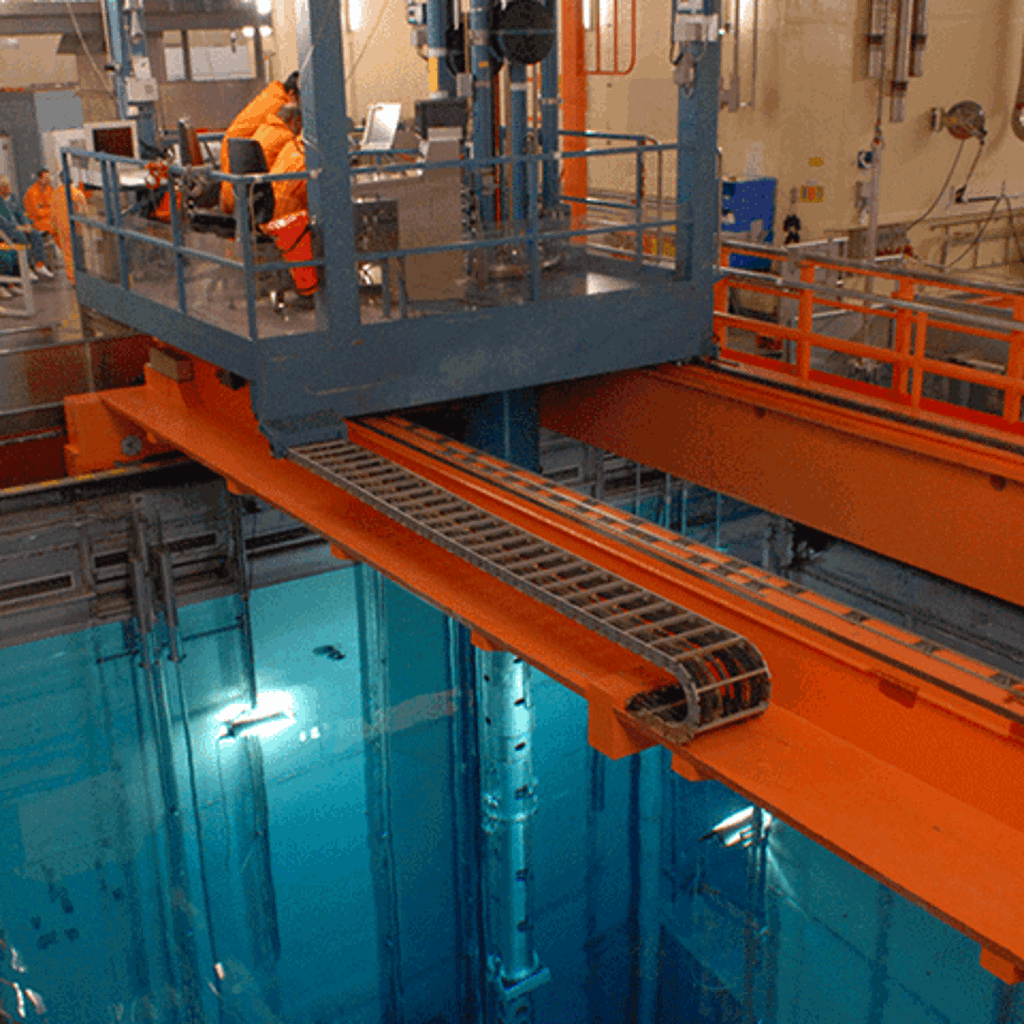

SOSA - Shorten the reload time of you reactor core

SOSA allows you to shorten the reload time of your reactor core. The program supports you in simplifying the shuffle plan. SOSA is applicable in any situation and aims to minimise the movements of the refuelling machine. Your reload time can be shortened by 4-14 hours! Additionally, your personnel receives a lower radiation dose.

Nuclear Fuel Management Software for Ringhals NPP

Fuel cost savings of €500.000 per cycle and an increase of the assembly discharge burnup of 1,5%. Vattenfall realised a significant operating cost reduction for their nuclear installations. A challenging task! Especially hard to achieve because of the complex core design of the 4 operational reactors.

- Cost saving of €500.000

- Increase of the assembly discharge burnup of 1,5%

- Applied in Ringhals 2-4

ROSA clients around the world

Vogtle - 1,2,3,4 (US), Farley - 1,2 (US), Watts Bar - 1,2 (US), St Lucie - 1,2 (US), Point Beach - 1,2 (US), Turkey Point - 3,4 (US), Seabrook (US), Seqouyah - 1,2 (US), V.C. Summer (US), Koeberg - 1,2 (SA), Grohnde (DE), Isar-2 (DE), Brokdorf (DE), Grafenrheinfeld (DE - EOL), Krsko (SI), Borssele (NL), Ringhals - 2,3,4 (SE) - Almaraz (ES) - Trillo (ES)

Meer weten?

We helpen je graag.