BLACKSTONE Program: Life Time Extension for EDF

NRG PALLAS has enabled life time extension of Advanced Gas Cooled Reactors (AGRs) operated in the U.K. by EDF.

More than 40 years

More than 40 years of AGR reactor life extension enabled since project launch in 2006

Excellent temperature control

Irradiation of graphite with excellent temperature control

+1000 measurements

Reliable data: Thousands of radioactive graphite property measurements performed

Jim Reed

Chief Graphite Engineer, EDF

Leading Supplier of Innovative Energy Solutions

Jim has worked for EDF for 40 years and has been Chief Graphite Engineer since 2018, leading all technical engineering projects in the Graphite Branch.

- One of the UKs biggest low carbon energy suppliers

- 20% of the UK’s energy needs is generated by EDF

- 5m customers in the UK

- Aims to achieve CO₂ neutrality by 2050

Continued operation of Advanced Gas cooled Reactors

EDF has commissioned the BLACKSTONE irradiation program at NRG PALLAS to provide essential data for the continued operation of Advanced Gas cooled Reactors (AGRs) in the U.K. The graphite irradiations in the High Flux Reactor (HFR) mimic and accelerate the aging mechanisms that take place in an AGR. Data from characterization of the irradiated graphite specimens is used to inform models to underwrite the safe and economic operation of AGR stations for the coming years.

The expertise and quality of NRG PALLAS irradiations and measurements, in combination with analysis support from Frazer Nash Consultancy and ATKINS, is recognized by both EDF and the UK regulator The office for Nuclear Regulation (ONR). Data from BLACKSTONE is used in safety studies, on the basis of which a total combined 40 reactor years of lifetime extension have been added to 14 reactors across the AGR fleet.

Advanced Gas cooled Reactors: an introduction

8 Advanced Gas cooled Reactors (AGRs) on 4 sites are operated in the U.K. by EDF. Each reactor core is built from graphite bricks that moderate neutrons in order to sustain the nuclear chain reaction. Reactor fuel and control rods are positioned between the graphite bricks, and reactor cooling is provided by CO₂ gas. The core structure ages due to the combined effect of irradiation damage and oxidation of the graphite bricks. Neutron irradiation causes dimensional change of the graphite bricks. The strength of the graphite is reduced by oxidation and due to the dimensional change and thermal stresses cracking of bricks is initiated.

In order to secure continued operation of AGR stations and optimize inspection regimes, knowledge is required on how the graphite bricks develop beyond current operating conditions. The graphite in the reactor core cannot be replaced and is critical to the operating lifetime.

BLACKSTONE program

In a unique experimental program, aging of the graphite is accelerated approximately 5-10 times to extend the database with irradiated graphite properties. As part of the Blackstone program, the following activities were undertaken in each of the three phases of the program:

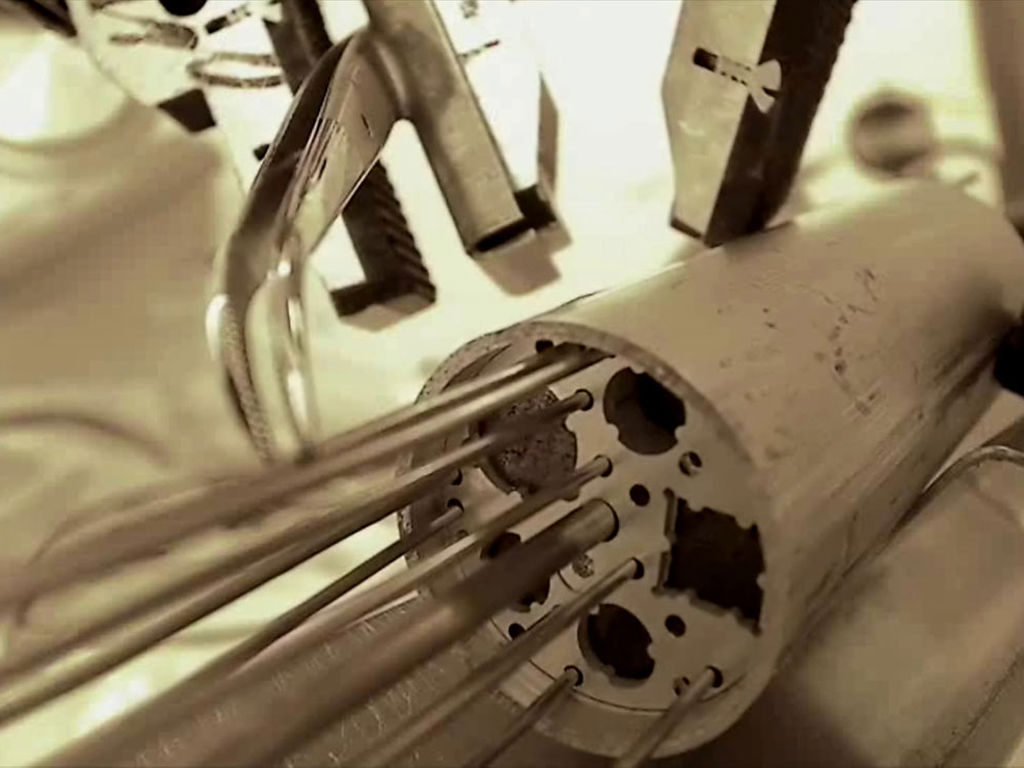

- Transport of radioactive graphite from the U.K. to NRG PALLAS

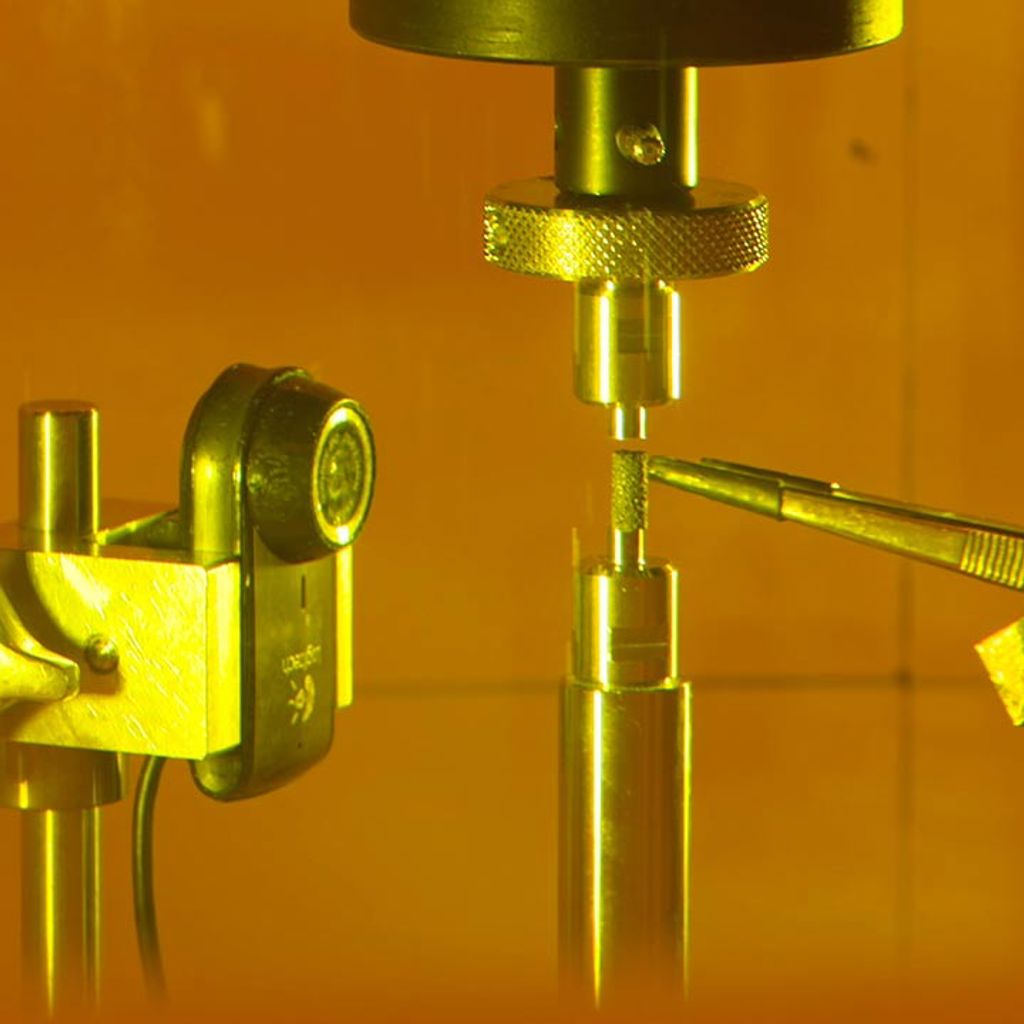

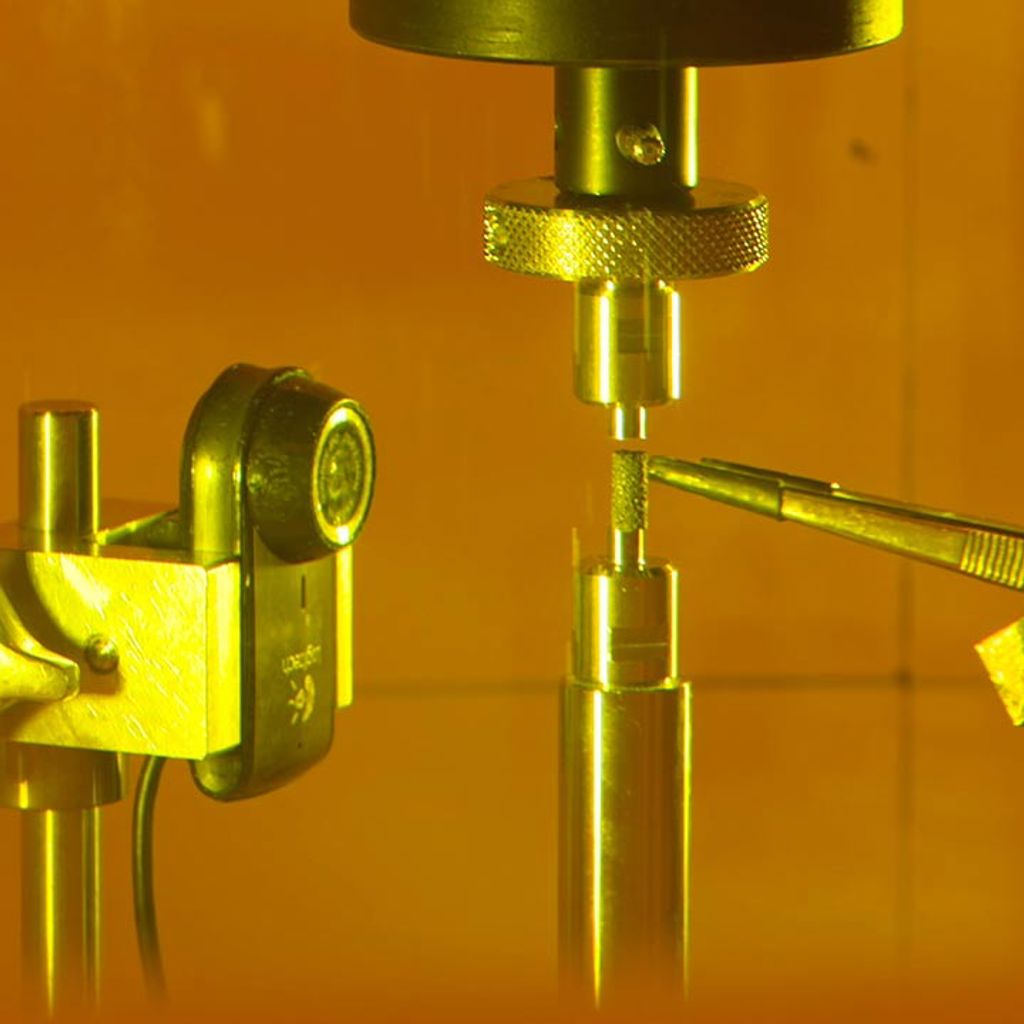

- Engineering of irradiation capsules in which the graphite specimens are loaded in the High Flux Reactor

- Irradiation of graphite specimens in the HFR

- Extensive characterisation of graphite before and after irradiation in the Hot Cell Laboratories.

By using the High Flux Reactor, graphite specimens extracted from AGRs are irradiated under conditions that are similar to an AGR but faster. The graphite specimens are characterised in the Hot Cell Laboratory to analyse the relevant properties that change with irradiation:

- Dimensional change

- Weight loss

- Thermal properties, e.g. conductivity and thermal expansion

- Mechanical properties, e.g. flexural strength

We can now compare the data from the trepanned samples with what we expected, which results in more efficient analysis of reactor data

- Jim Reed, Chief Graphite Engineer at EDF Energy

Representative data for reactor safety cases

The main challenge of the BLACKSTONE program is to provide irradiated graphite property data that is fit for purpose and in time data to inform safety cases for lifetime extension.

The irradiation conditions are carefully controlled to ensure that the accelerated aging of graphite in the HFR is representative for AGRs. The target temperature of 420°C is achieved by a combination of accurate design, fabrication of components, and online monitoring. Oxidation of graphite specimens is controlled by feeding a mixture of CO₂ through the irradiation rig and continuously measuring ingoing and outgoing gas compositions.

Characterisation of the specimens is carried out in the hot cell laboratories by expert personnel to the strictest quality requirements. Through statistical analysis of the data and structural analysis of the graphite specimens, it is assured that representative data is acquired. The results of thousands of measurements are then used to combine with AGR reactor inspection data.

Graphite irradiation creep

Graphite components in a reactor are stressed and change dimensions when subjected to neutron irradiation. Stresses that are induced in the material by irradiation can be relieved be a mechanism known as creep. A dedicated irradiation test was developed by NRG PALLAS to study this mechanism and provide data that feeds into AGR graphite material models. The test consists of graphite specimens that are subjected to a high load applied by gas-filled bellows. Different modules with specimens and bellows are placed in an in-core position in the HFR and irradiated for multiple cycles. By measuring the dimensional changes of stressed and un-stressed graphite specimens, the effect of irradiation creep is determined.

How does EDF experience the cooperation?

Jim Reed: NRG PALLAS is a learning organisation. EDF were a very competent technical organistation in our own right and NRG quickly realised the path to success was not a supplier-customer arrangement but a much more team-work and collaboration.

NRG PALLAS also have the skills and experience to know what was easy and what was trickier. They were able to develop a programme with milestones and earmarked key risks. These risks were managed in an effective way that NRG PALLAS were delivery focused and goal orientated. This made the project a success.

There were two parts to the programme – doing the right experiment and doing the experiment the right way. The unique NRG PALLAS infrastructure made the second part achievable because the relevant technical expertise, the reactor, and hot cells were all in place. If something was not present, or not suitable for our experiment, NRG PALLAS quickly adapted to put the necessary arrangements together.

That is why NRG PALLAS is a very valuable partner for us.

- NRG's technical capacity to "do the right experiment"

- Excellent temperature control

- New and unique gas chemistry to achieve radiolytic oxidation

- High-quality pre- and post-irradiation sample measurements of important graphite properties

What are the main benefits of Blackstone for EDF?

The BLACKSTONE program and the graphite irradiation creep program has generated data to extend the combined reactor life of the AGR fleet by more than 40 years.

With the successful acquisition of the leading MTR data, we can now compare the data from the trepanned samples with what we expected. This allows a much leaner trepanning programme and it supports a much more efficient analysis of the reactor data. This helps EDF and the regulator build confidence that the reactors are ageing and degrading as expected.

Interested?

We're happy to help.

Marjolijn Droog