MSR Research Program

Our Research Program helps bringing MSR technology closer to reality through accurate reproduction of in-use conditions. NRG is your partner for the development and qualification of materials and fuels for Molten Salt Reactors.

About NRG PALLAS Molten Salt Reactor Research Program

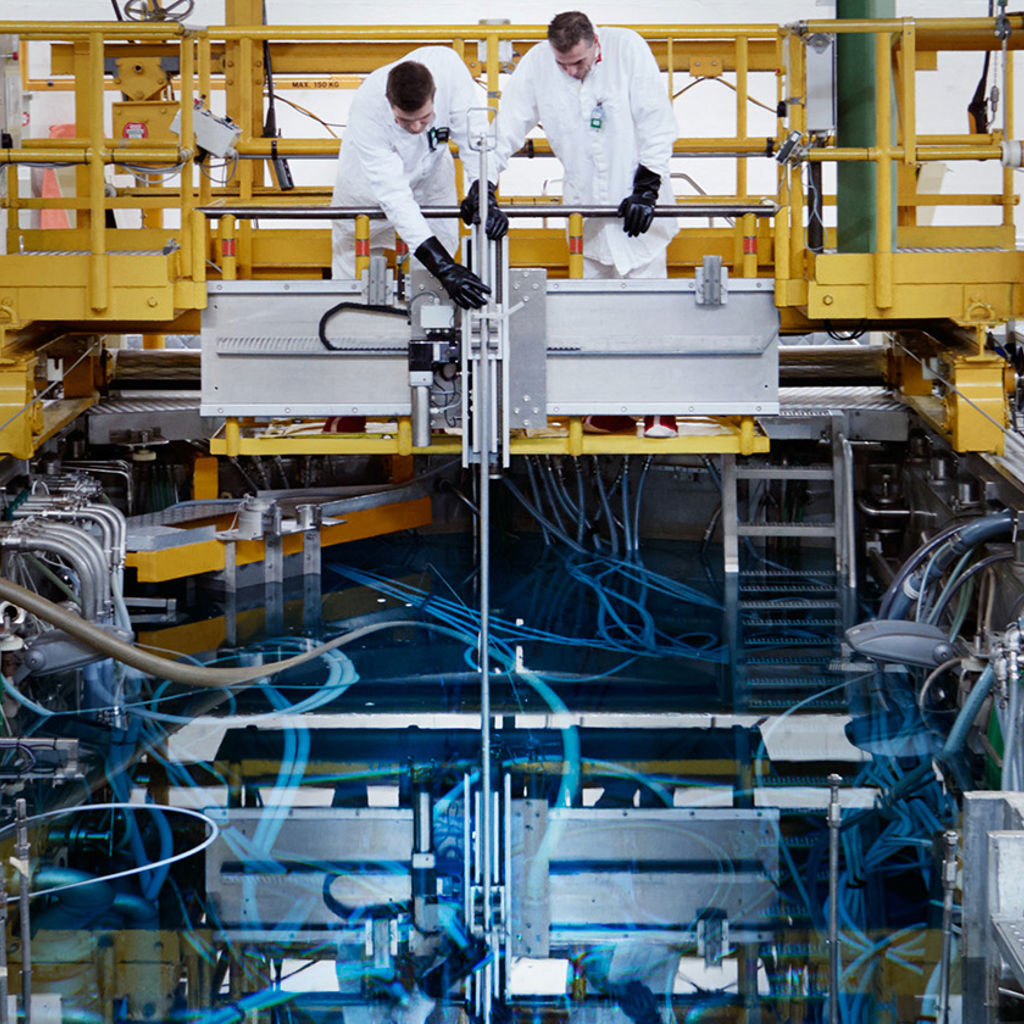

NRG PALLAS has extensive experience with material and fuel tests for existing and advanced reactors, supported by the full nuclear infrastructure available in Petten.

Due to the growing global interest in molten salt reactors (MSRs), a decision was made in 2015 to launch an ambitious research program to meet the specific needs related to MSR development. This MSR program was set up within the Dutch government’s nuclear technology research program, funded by the Ministry of Climate and Green Growth, and partly through European Horizon 2020 projects such as SAMOSAFER, MIMOSA, and ENDURANCE.

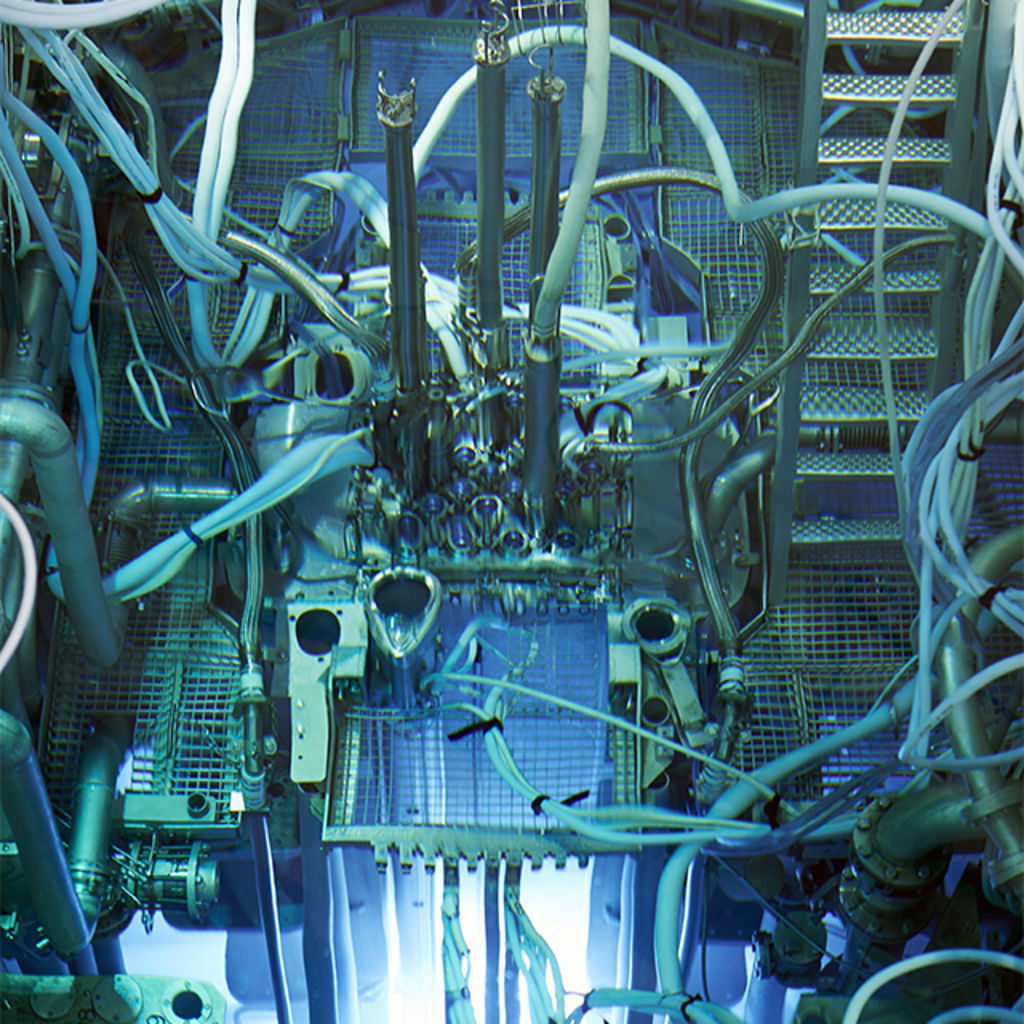

The core of the program is a series of irradiation tests that simulate the physico-chemical processes occurring during reactor operation. Examples include corrosion of metallic structural materials in radioactive salt, weakening of materials due to temperature and radiation, deposition of fission and corrosion products on pipe walls, and gas formation.

Projects within this program are coordinated from Petten, where most of the activities take place. To strengthen the program, collaborations have been established with research centers possessing complementary expertise, such as the European Commission’s Joint Research Centre (JRC), Delft University of Technology (Netherlands), CV Rez (Czech Republic), SINAP (China), and IFE (Norway).

Projects of the Molten Salt Research Program

The program is built from a diverse set of technically challenging projects. Here are some highlights.

Salient-01

SALIENT-01 was the first irradiation of fissile salt in a test reactor in 45 years and is well-known in the MSR community.

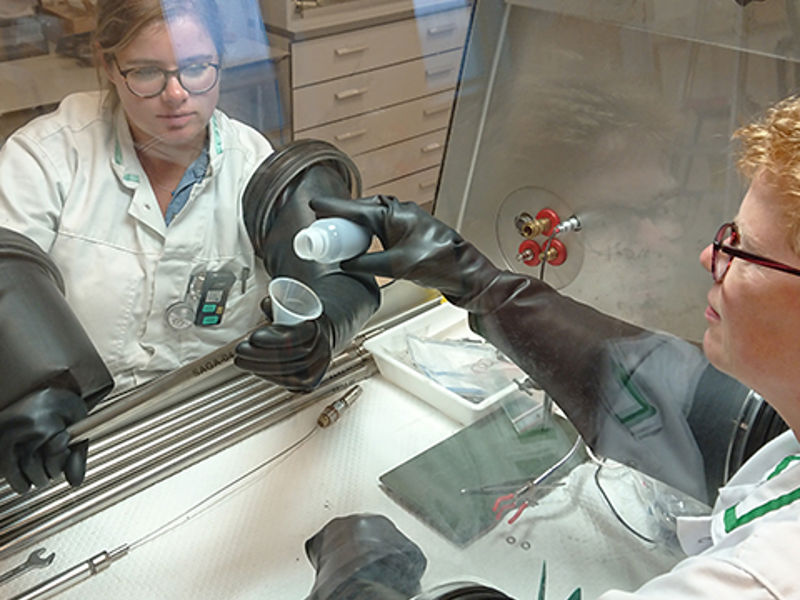

The main goal was to gain knowledge and experience in molten salt irradiation: designing an experiment with liquid fuel, handling fresh and irradiated fuel salts in inert environments, and processing the resulting waste.

In summary, mixtures of lithium fluoride and thorium fluoride were placed in graphite holders and exposed to intense neutron and gamma radiation in the HFR Petten. The irradiation caused fission reactions in the salt samples, producing the heat required to melt the salt.

Salient-03

The follow-up to SALIENT-01, SALIENT-03 focuses on metal corrosion by molten fluoride salt in a radiation field and on measuring gas release during irradiation.

Lessons from SALIENT-01 were incorporated into the design. The experiment is conducted in collaboration with the European JRC, which produces and characterizes the salts and contributes to the design process.

Enickma

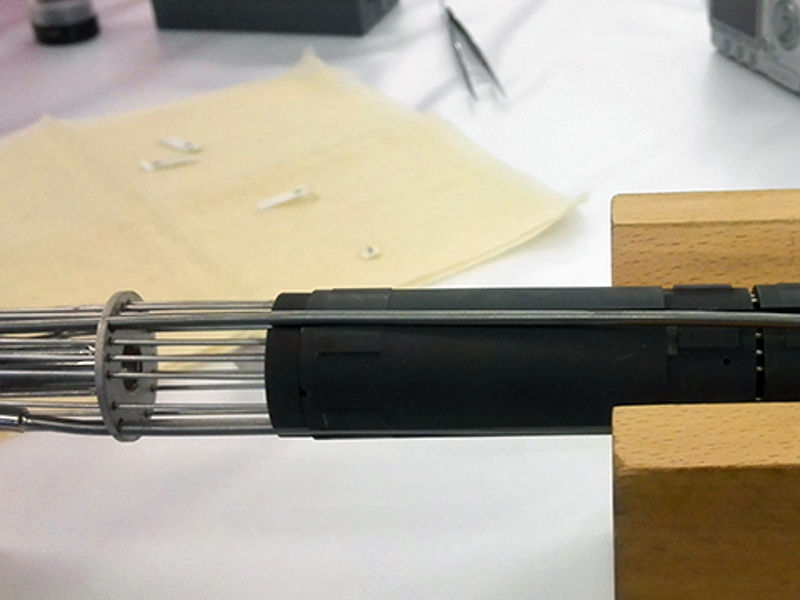

Nickel alloys (and potentially certain steels) are considered materials for MSR primary systems due to their good corrosion resistance. However, nickel is sensitive to thermal neutron fields, where neutron capture can produce helium. This helium production can lead to embrittlement of the material.

The ENICKMA irradiation aimed to map this embrittlement effect in candidate alloys for MSRs, including Hastelloy N. Over 100 tensile specimens were irradiated at MSR-relevant temperatures. Results from irradiated samples were compared with unirradiated reference samples. The findings showed significant embrittlement in nickel alloys, while a reference steel's properties were barely affected by neutron exposure.

ENICKMA-HTC (High Temperature Creep)

A successor to ENICKMA, this irradiation also investigates radiation-induced embrittlement of MSR construction materials, but takes it a step further by also examining mechanical creep during irradiation.

The project has two main parts. The lower half replicates ENICKMA but with higher doses and a greater focus on steel alloys based on prior results. The upper half involves a tensile-creep test on three stainless steel samples, measuring their slow elongation during irradiation. The same test is also conducted in an oven to distinguish between temperature and radiation effects.

IFE (Norway) is a partner in this project, contributing expertise in in-pile instrumentation and in the design, construction, and operation of instrumented irradiation facilities. The project is part of the OECD/NEA FIDES II program.

FAQ

You have questions about Molten Salt Reactors. We have combined all frequently asked questions... and answered them.

SAGA

SAGA aims to study gas formation when fluoride (and possibly chloride) salts are exposed to a strong gamma field at temperatures below 100–150°C. This phenomenon could pose problems for temporary storage of spent fuel salts and in certain accident scenarios.

The reusable SAGA facility includes six gas-tight sample holders, each connected to a pressure sensor. These sensors record gas pressure buildup during irradiation of the facility in the gamma field of spent HFR fuel rods.

Salt Waste Treatment

The development of new nuclear technologies like the MSR also demands suitable routes for handling the salt-based fuel waste, ensuring safe disposal for people and the environment. The LUMOS Waste project addresses this by studying the waste from the SALIENT experiments.

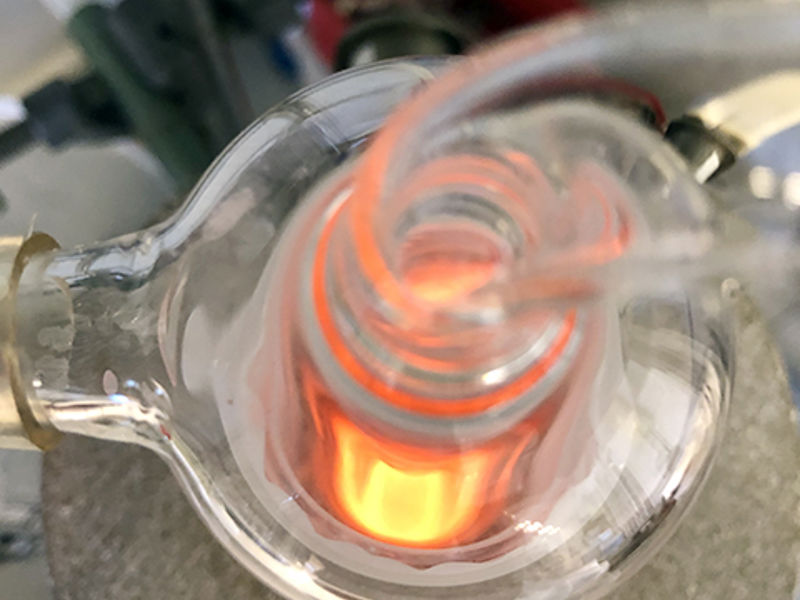

NRG PALLAS is in discussions with COVRA (the Dutch radioactive waste authority) to define the requirements for the processed waste to be accepted for storage. It begins with a full analysis of all components. Several methods were tested for chemical stabilization, with the best results achieved by high-temperature dehalogenation in contact with glass formers, leading to vitrification of the waste.

Cooling system simulation

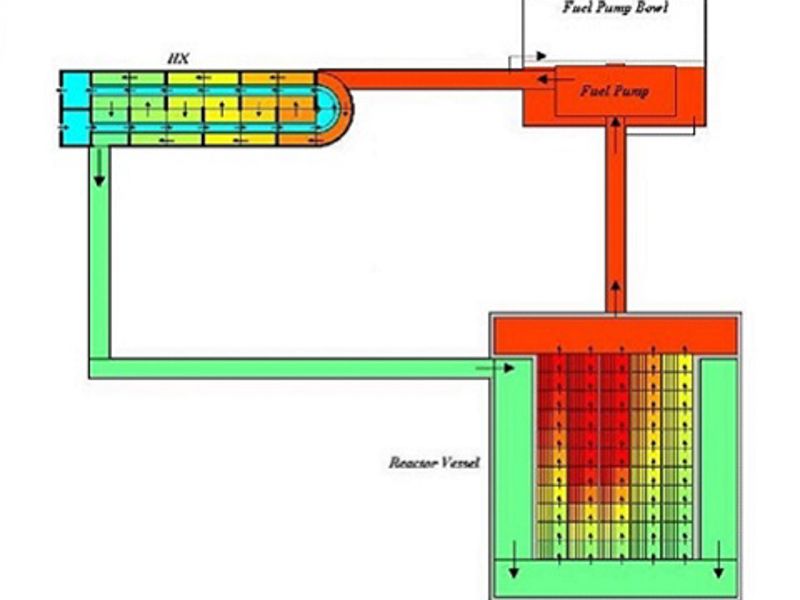

For design support and safety analyses one should know the molten salt flow and heat transport in the reactor vessel and/or the cooling system. For this, so-called thermal-hydraulics system codes were used. The nuclear reactor is modelled in such codes by ways of 0- or 1-dimensional elements. Originally, such codes were developed for water cooled reactors.

The simulation code needs to be adapted for molten salt reactors. Besides, validation is required to gain trust in the simulation outcomes. The SPECTRA code of NRG has been adapted for the specific and unique requirements put forward by modelling molten salt reactors. The following models are now available in the code

- Flexible user input for molten salt material and transport characteristics

- Fission product transport

- Delayed neutron precursor drift

Besides, the flow in the reactor vessel demands 3-dimensional modelling. For that reason, NRG started to prepare also a 3-dimensional tool for simulation of molten salt reactors.

Partnerships & collaboration

More info about the MSR Program?

We're happy to help.