Qualification of First Wall Panels for ITER

Temperature control

Irradiation of ITER First Wall Assemblies with excellent temperature control

Components

Full sub scale component irradiation at ITER representative temperature

Tests

First high heat flux tests on neutron irradiated first wall component for ITER

In 2016 NRG concluded the first part on the Qualification of the ITER First Wall Assemblies, the second part is conducted at the premises of project partner Forsungzentrum Juelich in 2018.

History on nuclear fusion R&D projects at NRG PALLAS

Alongside the exploitation of the High Flux Reactor in Petten, since 1960 a long term R&D programme on fusion material research was conducted. In this programme material qualification tests of Reduced Acivating Ferritic Material for ITER were performed and the European selection of candidate fusion fuel material for ITER was made. In addition many other fusion materials for various applications in fusion reactors were irradiated under ITER and fusion reactor representative irradiation conditions and subjected to extensive post irradiation research campaigns.

In 2005 decision was made to build ITER in the South of France and the first agreement was made to develop a joint undertaking for European Fusion Energy research and development for ITER which led to the resurrection of Fusion for Energy. This led to major reorganisations of fusion research funding structures of EURATOM and the decision to organize the EU long term fusion research in the European Joint Programme EUROFUSION from 2014 onwards. The Dutch subsidy from the ministry of economic affairs for long term fusion research stopped in 2016.

With the primary focus towards the building of ITER, the extensive network of fusion partnerships and the expertise and quality of NRG PALLAS irradiations and measurements, resulted in 2012 in a contract research assignment from ITER for the nuclear qualification of first wall panels.

ITER: an introduction

ITER is an international collaboration project with seven partners EU, China, Korea, Japan, US, Russia and India. The objective of ITER is to generate a net overall energy production rate from a fusion plasma. It will be the largest tokamak ever build until to date.

Unlike the process in a nuclear reactor where energy is generated from the nuclear fission of Uranium atoms, energy in a hot plasma is generated from the fusion of two hydrogen atoms, emitting a helium atom and a neutron. This process requires extreme high temperature of the plasma (above 1 million deg. C). Fortunately the plasma can be controlled with magnetic field coils surrounding the ITER vessel.

The neutron emitted from the hot plasma will be shielded by the ITER First wall, this consists of a layer of Beryllium joined to a Copper alloy which functions as a heat sink material. ITER will not generate electricity to the grid, but will be the first tokamak in the world to prove that that it fusion power for electricity production is feasible.

The First Wall component Irradiation

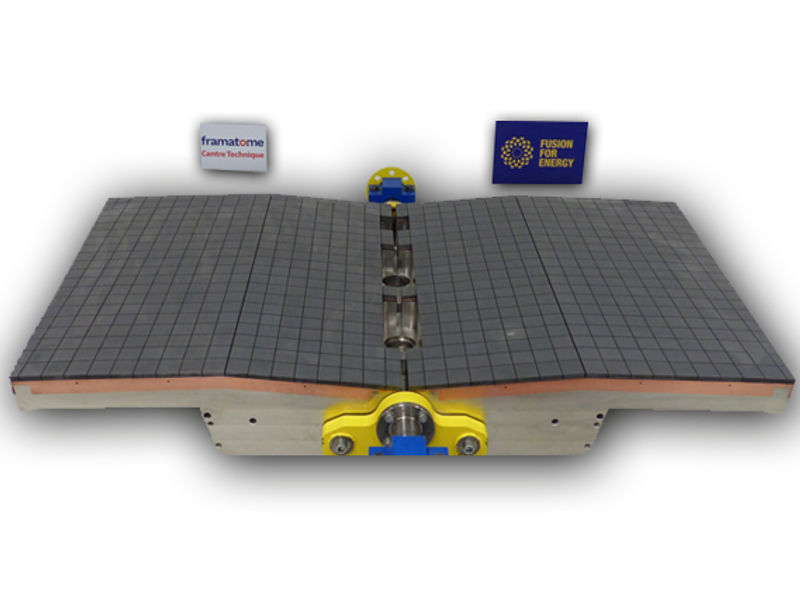

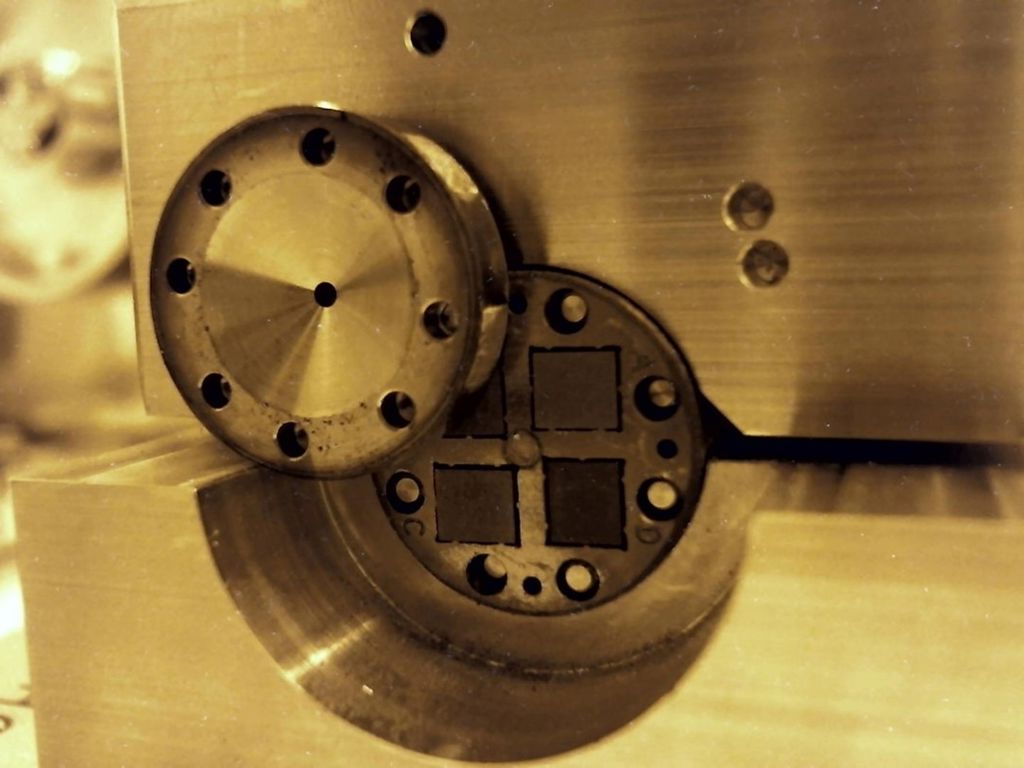

Together with the ITER First Wall team, the Chinese and Russian material suppliers and project partner Forsungszentrum Juelich, the first nuclear material qualification test was conducted. The first wall components were irradiated to ITER representative neutron fluence and temperature. The objective was to investigate the joint of the beryllium clad and the copper alloy heat sink material and to evaluate changes in thermal profiles of the component during High heat flux testing in the JUDITH- 1 facility at FZJ. The following activities are undertaken in each phase of the program:

- Delivery of the sub scale ITER FW panel from the Chinese institute xxx and the Russian institute yyy

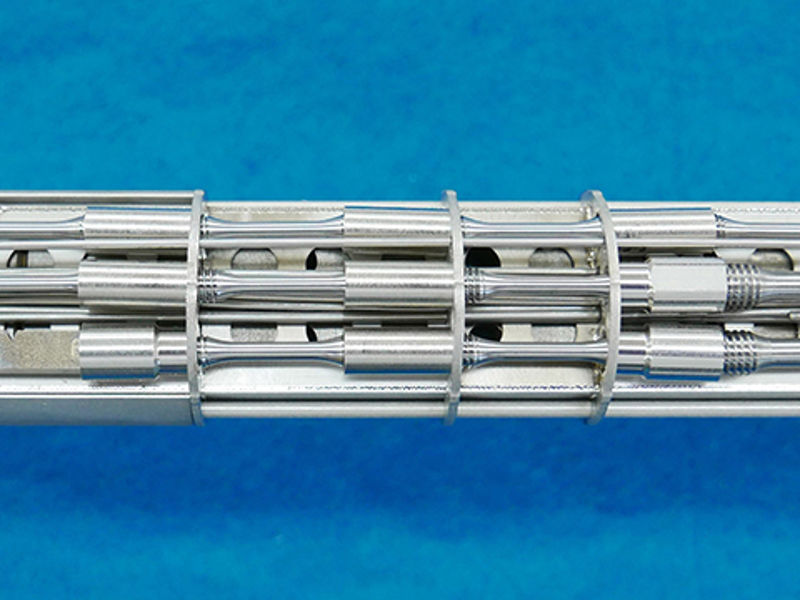

- Engineering of irradiation capsule in which the components are loaded in the High Flux Reactor

- Irradiation of ITER FW components in the HFR

- Before and after irradiation High Heat flux testing with ITER representative heat loads using the electron beam in the JUDITH- 1 facility in FZ Juelich

- Nuclear transport of irradiated components to FZ Juelich

Accurate irradiation data for ITER

The main challenge of the HESTIA irradiation in the HFR is to mimic the similar neutron irradiation conditions as in ITER, within a short period. This will be used to simulate radiation damage during the life span of the component in ITER in order to predict how long these components will maintain the integrity and functionality.

After irradiation, the irradiated mock-ups are transported to Julich research centre, where they are exposed to extremely high heat flux and intense variable thermal radiation. This can determine whether the irradiated material offers sufficient resistance to extreme heat load in the ITER system.

In the experimental design of the HESTIA irradiation device, special care was undertaken to keep the temperature uniform and constant throughout the full irradiation.

This was done by engineering of heat conduction blocks, surrounding the ITER FW components and with precision manufacturing of these blocks, a constant and uniform temperature of 240 C was kept during irradiation .

Results and benefit

The fusion R&D program in general and the ITER first wall qualification project has generated data predict the behaviour of the first wall components. In addition nuclear competences have been further developed for future irradiation qualification and research programmes for many other clients and organisations.

Qualification of nuclear graphite

NRG PALLAS has decades of expertise in nuclear graphite research, supporting next-generation reactors by qualifying graphite grades for high-temperature use.

In Generation IV reactors, graphite is vital as structural material and moderator under extreme conditions. Understanding its irradiation behavior is essential for licensing.

Through advanced capsule designs, precise temperature control, and cutting-edge techniques, we deliver reliable data to drive innovation.

Together with Terrestrial Energy, we launched the GAIA project at the High Flux Reactor (HFR) in Petten, irradiating graphite grades for the Integral Molten Salt Reactor (IMSR). GAIA provides a unique dataset covering the full lifetime of IMSR graphite components, strengthening design and safety.

NRG PALLAS, your trusted partner in advancing graphite technologies.

Advancing materials for the next generation of reactors

Advanced nuclear reactors require structural materials that can withstand extreme temperatures, corrosive environments, and intense neutron irradiation. To meet these challenges, NRG PALLAS is leading cutting-edge research on nickel-based alloys, key candidates for molten salt reactors (MSRs).

Through the ENICKMA project, we are irradiating several nickel alloys and stainless steel at ~650°C and ~725°C in the High Flux Reactor (HFR) to study degradation mechanisms such as helium embrittlement and thermal aging.

Building on this work, we are developing ENICKMA-HTC, which will focus on the in-pile and out-of-pile tensile creep behavior of these materials under MSR-relevant conditions.

With these projects, NRG PALLAS is helping pave the way for safe, reliable materials qualification for Generation IV nuclear power plants.

Advancing safe, long-term operation of nuclear reactors: impact NRG PALLAS

At NRG PALLAS, advancing the long-term safe operation (LTO) of nuclear reactors is a core mission. Through cutting-edge irradiation testing, materials science, and international collaboration, we support the continued operation of both power and research reactors—critical for clean energy, medical isotopes, and nuclear innovation.

A flagship project is STRUMAT-LTO (2020–2024), funded by H2020 EURATOM and coordinated by NRG PALLAS. STRUMAT-LTO advanced the understanding of reactor pressure vessel (RPV) embrittlement, crucial for extending Pressurized Water Reactor (PWR) lifetimes. Key achievements include:

- Irradiating 20 RPV model steels and welds with varied compositions at the High Flux Reactor (HFR).

- Identifying nanometer-scale solute clusters as a primary embrittlement cause.

- Validating Mini-CT specimens for fracture toughness testing.

- Demonstrating the potential of thermal annealing for material recovery.

- Completing 1600+ mechanical tests and 20+ scientific publications.

- Training future experts through international workshops and a summer school.

Building on this success, NRG PALLAS has launched Magic-RR (2024–2028), a EURATOM-supported project to ensure the continued safe operation of Europe's aging research reactors. Magic-RR focuses on aluminum alloy behavior under irradiation, corrosion mitigation, and modern aging surveillance methods.

By leading projects like STRUMAT-LTO and Magic-RR, NRG PALLAS plays a key role in securing Europe's safe, low-carbon nuclear future.

More information about ITER?

We are happy to tell you more.